Today we got the chaff and straw blown off the combine, so we wouldn't get dusted out too bad when we took the concaves out. With a good wind blowing, we opened up all the shields and blew out all the dust that had been hiding in the guts of the combine. Once the coast was clear, we pulled out the middle of the three concaves and started pulling wires.

This is the middle concave with the wires as they should be...considered a "small wire" concave. This one works fine for small grains, but since we were going to be moving on to soybeans, the spaces had to be wider. We did...or do...have a set of wide wire concaves from back at home, but when Al went to find them when he was home for the hockey game, they had "disappeared". So we had to do it the old way...pull every second wire.

This is the middle concave with the wires as they should be...considered a "small wire" concave. This one works fine for small grains, but since we were going to be moving on to soybeans, the spaces had to be wider. We did...or do...have a set of wide wire concaves from back at home, but when Al went to find them when he was home for the hockey game, they had "disappeared". So we had to do it the old way...pull every second wire.We got that done without too many problems. Marilyn made a point of numbering them all, so when we have to put them back in, it will go a lot smoother...we hope.

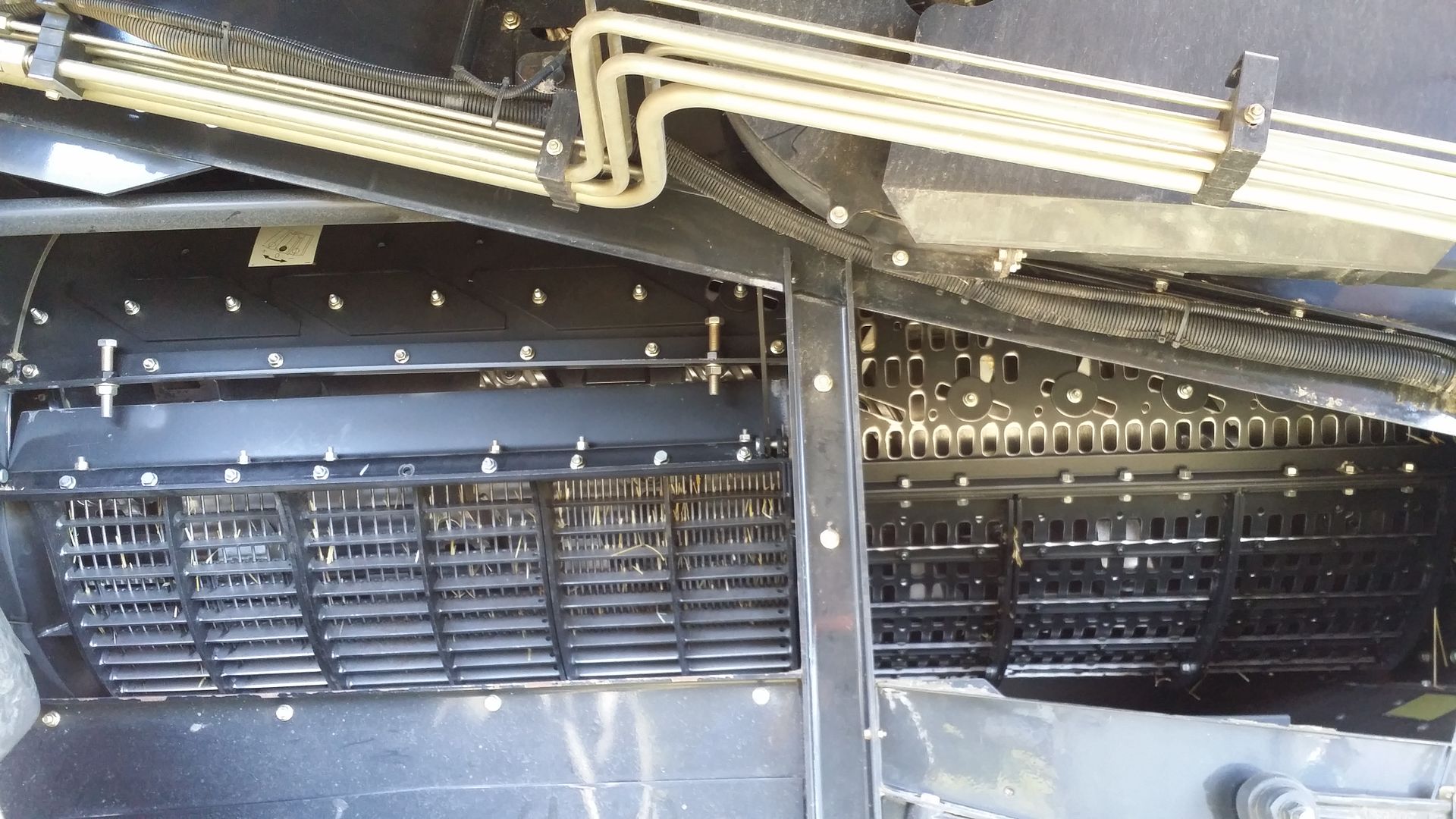

Once we got that one finished, we took the front concave out. It has an extra collar on it and there are "disrupter" bars, that fill in the gaps to make more threshing area. This picture shows the wires pulled on half of the concave...and Al's hammer.

We finally had the wires pulled and the concaves back in the combine. This picture shows the difference between the front two concaves on the left, and the third one. It was now time to get it set for soybeans, then go out and do a test. Kim got his combine cleaned off and ready...he had different concaves and didn't have to do any pulling, so he was ready in no time.

We moved over to the bean field a few miles east, then got the header into "flex" mode. W haven't combined soybeans for several years now and not since we have been running the MacDon header, so we were eager to see how it would work. First we had to get the manual out to see if we had done everything right.

Kim was working with his Honeybee header, which was a draper, similar to ours, but it was not a flex draper. He had never combined beans, so had no idea of what to expect. It didn't take long before he had it "sort of" figured out and we were both making dust.

Were we ever making dust. With what ever wind was blowing and the combination of bean dust and road dust along the outside rounds, it was almost impossible to see where we were going. As you can see...or not see...from this view out the combine window. Al was doing the combining and Marilyn was co-piloting. That job included going out to take the rocks off the header that had been picked up from running the header on the ground.

As the evening wore on and the wind died down, the dust was just creeping low across the field.

We got the semi loaded, then headed back for the farm. We thought we would celebrate the first of the beans, with a Blizzard from Dairy Queen, so we went home through town. They were closed for Thanksgiving. Curses. Leftover pumpkin pie filled the gap.

And, of course, another beauty of a sunset...

No comments:

Post a Comment